What is a Drop Tester?

A Drop Tester is a device designed to simulate the impact forces that a packaged product may experience during shipping. The tester drops a product, typically inside its protective packaging, from a set height onto a hard surface, such as concrete or steel. This helps manufacturers assess whether their packaging can protect the product inside from impact-related damage.

By performing Drop Testing, manufacturers can evaluate the effectiveness of their packaging designs, identify weaknesses, and make improvements to ensure that their products remain safe during transit.

Why Drop Testing is Crucial for Packaging Safety

1. Protecting Products During Transport

The main purpose of packaging is to protect products from damage during transit. Whether products are being shipped in bulk or individually, packaging must withstand physical forces like drops, impacts, and pressure from stacking. A Drop Tester simulates these conditions to assess how well packaging performs when subjected to sudden impacts.

By conducting Drop Tests, manufacturers can evaluate their packaging’s shock-absorbing capabilities and determine if it is strong enough to safeguard the product inside. This reduces the likelihood of damaged products and returns, which ultimately saves costs and preserves brand reputation.

2. Meeting Industry Regulations and Standards

Many industries have specific standards and regulations regarding packaging strength. In industries like electronics, food, and pharmaceuticals, the packaging must ensure that products remain safe and intact during shipping. For instance, electronics packaging must protect delicate components from drops, while food packaging must ensure the product is kept intact and uncontaminated.

Drop Testers allow manufacturers to test whether their packaging complies with these industry standards. Meeting regulatory requirements ensures that products are safe for consumers and helps manufacturers avoid legal issues, fines, or product recalls.

3. Optimizing Packaging Design for Cost and Efficiency

Packaging design is a delicate balance between cost, material efficiency, and protection. Over-packaging leads to wasted materials, resulting in higher production costs. Under-packaging can lead to product damage and increased returns. Drop Testing helps manufacturers optimize packaging designs by identifying the minimum strength necessary to protect the product without using excess material.

The data obtained from Drop Tester helps manufacturers fine-tune their packaging designs, ensuring that packaging is strong enough to prevent damage but not over-engineered to the point of wasting materials. This leads to more sustainable, cost-effective packaging solutions.

4. Reducing Risk of Damage and Returns

Product returns due to damaged packaging are costly for manufacturers and harmful to their reputation. Packaging failures during transit often result from insufficient strength, improper design, or incorrect material use. Drop Testing helps manufacturers identify potential failure points in packaging before products are shipped, reducing the risk of damage and returns.

By ensuring that packaging is durable enough to withstand the rigors of transport, Drop Testers contribute to higher customer satisfaction and lower return rates, making them a valuable investment for manufacturers.

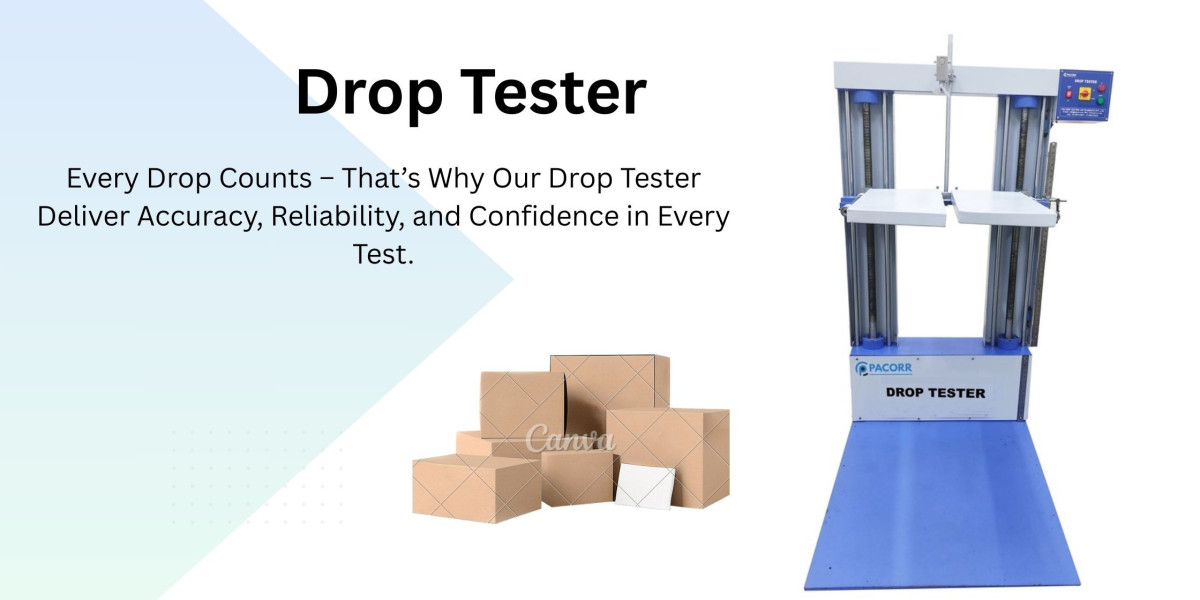

How Does a Drop Tester Work?

A Drop Tester simulates real-world shipping conditions by dropping a packaged product from a predetermined height onto a solid surface. The height, drop angle, and surface type can be adjusted to simulate various transport and handling scenarios.

Here’s an overview of how the process typically works:

The product, in its packaging, is placed inside the Drop Tester.

The product is dropped from a specific height onto a hard surface (e.g., concrete or steel).

The Drop Tester records the impact force and checks for any damage to the packaging or product.

The results are analyzed to determine if the packaging adequately protected the product or if modifications are necessary.

This test allows manufacturers to simulate drops from different heights and angles to replicate various real-world conditions.

Key Features of a Drop Tester

Adjustable Drop Heights: Drop Testers allow operators to adjust the height from which the product is dropped, simulating different shipping conditions, such as stacked products or drops from varying heights.

Customizable Testing Conditions: Drop Testers can simulate drops onto different types of surfaces (e.g., concrete, steel, or foam), mimicking various transport environments and impact scenarios.

Precise Impact Measurement: The tester measures the force of the impact and records any damage to the product or packaging, helping manufacturers assess the effectiveness of their packaging design.

User-Friendly Interface: Most modern Drop Testers come with intuitive interfaces that make it easy for operators to set up and monitor tests, as well as analyze results.

Data Logging and Reporting: Drop Testers often feature data logging capabilities that store test results, making it easier for manufacturers to track performance over time and generate detailed reports.

Applications of Drop Testers

Electronics Manufacturers: Drop Testers are essential for ensuring that packaging for electronic products, such as smartphones, laptops, and televisions, provides the necessary protection from impacts during shipping.

Packaging Manufacturers: Packaging companies use Drop Testers to validate their designs and confirm that their packaging solutions meet strength and durability requirements.

Food and Pharmaceutical Industries: Drop Testing helps ensure that food and pharmaceutical products are packaged in a way that protects them from physical damage during shipping while maintaining product integrity.

E-Commerce and Retail: Retailers, especially in e-commerce, rely on Drop Testers to ensure that their products are securely packaged for shipping, reducing the likelihood of product damage and improving customer satisfaction.

Industrial Goods: For large, heavy-duty industrial products, Drop Testers help ensure that packaging can withstand the impact of drops and other stresses during transit.

Benefits of Using a Drop Tester

Enhanced Protection for Products: Drop Testers ensure that packaging provides the necessary protection, reducing the risk of product damage during shipping and handling.

Cost-Effective Packaging Solutions: By optimizing packaging designs, Drop Testers help manufacturers use the right amount of material, reducing waste and material costs.

Improved Packaging Designs: Data from Drop Testing helps manufacturers refine packaging, ensuring it is both durable and cost-efficient.

Regulatory Compliance: Drop Testers help manufacturers meet industry-specific packaging requirements, ensuring compliance with safety standards and preventing legal issues.

Conclusion

The Drop Tester Price is a vital tool for any manufacturer looking to optimize packaging durability and ensure product safety during transport. By simulating real-world impacts, Drop Testers provide valuable data that helps manufacturers improve packaging designs, reduce costs, and ensure products remain intact during shipping.

At Pacorr Testing Instruments, we offer high-quality Drop Testers that provide reliable and accurate testing to help you improve your packaging process. To learn more about how our Drop Testers can benefit your business, visit pacorr.com.